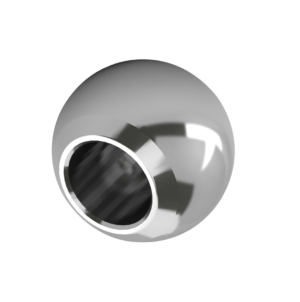

Modular Shell has following basic design features:

1. Modular Shell is manufactured from Ti-6Al-4V-ELI conforming to ASTM F136-13- “Standard Specification for Wrought Titanium-6Aluminum-4Vanadium ELI for Surgical Implant Applications” and ISO 5832-3:1996: ” Implant for surgery-Metallic material – Part-3, Wrought Titanium 6-Aluminium 4-Vanadium alloy” and is intended to be used with mating liner.

2. Modular Shell is designed as a hemispherical geometry, press-fit shell with a porous coating on outer surface and is intended to be implanted in prepared acetabulum without bone cement (Press fit cementless fixation).

Titanium powder being used for coating conforms to ASTM F1580-12: Standard Specification for Titanium and Titanium-6Aluminum-4 Vanadium Alloy Powders for Coatings of Surgical Implants and ISO 5832-2:1999 “Implants for surgery – metallic materials – Part 2: Unalloyed titanium”

Modular Shell has internal taper and circumferential locking undercut feature to facilitate taper locking and rim locking of modular HXLPE liner with modular shell.

3. Modular Shell is provided with a threaded apical hole at dome to attach instruments for surgical insertion in prepared acetabulum.

4. Two/Three screw holes are provided in modular shell for optional additional immediate fixation through bone screws. Smaller modular shell sizes (i.e. outer diameter 40, 42, 44 mm) contain 2 holes while rest of shell sizes contains 3 holes.

5. Eight/Twelve circumferential equidistant castellation (groves or tab cut outs) are provided to fit with anti-rotational lugs (tabs) of the modular HXLPE liner component. The smaller modular shell sizes (i.e. outer diameter 40, 42, 44 mm) have eight tab cutouts at every 45º and rest of the sizes have twelve tab cut outs at every 30º. Unused tab cut outs of shell are used for modular liner extraction, if required.

6. Modular Shell is available in different sizes based on outer diameter ranging from 40 to 70 mm in 2 mm increments.

Modular liner has following basic design features:

1. Modular Liner is manufactured from HXLPE (Grade: GUR 1020) conforming to ASTM F648-14: “Standard Specification for Ultra-High-Molecular-Weight Polyethylene (UHMWPE) powder and fabricated form for surgical implants.”

2. Modular Liner is available in different variants having different inner diameter (22 mm to 40 mm) and outer diameter (35 mm to 52 mm) to accept various sizes of modular femoral heads and modular shells respectively. Spherical outer geometry of modular liner fits closely with dedicated modular shell. Spherical inner geometry of modular liner is designed to suit dedicated modular femoral heads with diameters (Ø) ranging from 22 to 40 mm.

3. Modular Liner has external taper and external circumferential locking rim (protrusion) to achieve required press fit with modular shell for insertion and resistance to extraction.

4. Four/Six circumferential equidistant de-rotational lugs (tabs) are provided at the periphery of the external surface of the modular liner to fit in the castellations (grooves or tab cut outs) of modular shell. This anti-rotational tab locking feature provides anti-rotation stability to liner and also helps in visual check for full liner seating. Smaller modular liner sizes (i.e. outer diameter 35 & 37 mm) contain four de-rotation tabs located at every 90° while rest of the modular liner sizes contain six de-rotation tabs located at every 60°.

5. Modular Liner contains three circumferential equidistant (at every 120°) holes on top surface for surgical instrumentation used to insert the liner into modular shell.

| PART NO. | DESCRIPTION | SIZE |

|---|---|---|

| MSAC-40/35 | Modular Shell | 40/35 |

| MSAC-42/37 | Modular Shell | 42/37 |

| MSAC-44/37 | Modular Shell | 44-37 |

| MSBC-46/40 | Modular Shell | 46/40 |

| MSBC-48/40 | Modular Shell | 48/40 |

| MSBC-50/44 | Modular Shell | 50/44 |

| MSBC-52/44 | Modular Shell | 52/44 |

| MSBC-54/44 | Modular Shell | 54/44 |

| MSBC-56/48 | Modular Shell | 56/48 |

| MSBC-58/48 | Modular Shell | 58/48 |

| MSBC-60/52 | Modular Shell | 60/52 |

| MSBC-62/52 | Modular Shell | 62/52 |

| MSBC-64/52 | Modular Shell | 64/52 |

| MSBC-66/52 | Modular Shell | 66/52 |

| MSBC-68/52 | Modular Shell | 68/52 |

| MSBC-70/52 | Modular Shell | 70/52 |

| PART NO. | DESCRIPTION | SIZE | ||||

|---|---|---|---|---|---|---|

| HXLPE | HXLPE-75KGY | UHMWPE-1050 | HXLPE-VITAMIN E | E-CIMA 120KGY | ||

| MLAD-35/22 | MLAE-35/22 | MLAG-35/22 | MLAF-35/22 | MLAH-35/22 | Modular Liner | 35/22 |

| MLAD-35/28 | MLAE-35/28 | MLAG-35/28 | MLAF-35/28 | MLAH-35/28 | Modular Liner | 35/28 |

| MLAD-37/22 | MLAE-37/22 | MLAG-37/22 | MLAF-37/22 | MLAH-37/22 | Modular Liner | 37/22 |

| MLAD-37/28 | MLAE-37/28 | MLAG-37/28 | MLAF-37/28 | MLAH-37/28 | Modular Liner | 37/28 |

| MLAD-40/28 | MLAE-40/28 | MLAG-40/28 | MLAF-40/28 | MLAH-40/28 | Modular Liner | 40/28 |

| MLAD-40/32 | MLAE-40/32 | MLAG-40/32 | MLAF-40/32 | MLAH-40/32 | Modular Liner | 40/32 |

| MLAD-44/28 | MLAE-44/28 | MLAG-44/28 | MLAF-44/28 | MLAH-44/28 | Modular Liner | 44/28 |

| MLAD-44/32 | MLAE-44/32 | MLAG-44/32 | MLAF-44/32 | MLAH-44/32 | Modular Liner | 44/32 |

| MLAD-44/36 | MLAE-44/36 | MLAG-44/36 | MLAF-44/36 | MLAH-44/36 | Modular Liner | 44/36 |

| MLAD-48/28 | MLAE-48/28 | MLAG-48/28 | MLAF-48/28 | MLAH-48/28 | Modular Liner | 48/28 |

| MLAD-48/32 | MLAE-48/32 | MLAG-48/32 | MLAF-48/32 | MLAH-48/32 | Modular Liner | 48/32 |

| MLAD-48/36 | MLAE-48/36 | MLAG-48/36 | MLAF-48/36 | MLAH-48/36 | Modular Liner | 48/36 |

| MLAD-48/40 | MLAE-48/40 | MLAG-48/40 | MLAF-48/40 | MLAH-48/40 | Modular Liner | 48/40 |

| MLAD-52/32 | MLAE-52/32 | MLAG-52/32 | MLAF-52/32 | MLAH-52/32 | Modular Liner | 52/32 |

| MLAD-52/36 | MLAE-52/36 | MLAG-52/36 | MLAF-52/36 | MLAH-52/36 | Modular Liner | 52/36 |

| MLAD-52/40 | MLAE-52/40 | MLAG-52/40 | MLAF-52/40 | MLAH-52/40 | Modular Liner | 52/40 |

| PART NO. | DESCRIPTION | SIZE |

|---|---|---|

| CFNG-38/22 | Standard Cemented Cup Without snap fit Assembly | 38/22 |

| CFNG-40/22 | Standard Cemented Cup Without snap fit Assembly | 40/22 |

| CFNG-42/22 | Standard Cemented Cup Without snap fit Assembly | 42/22 |

| CFNG-44/22 | Standard Cemented Cup Without snap fit Assembly | 44/22 |

| CFNG-44/28 | Standard Cemented Cup Without snap fit Assembly | 44/28 |

| CFNG-46/28 | Standard Cemented Cup Without snap fit Assembly | 46/28 |

| CFNG-48/28 | Standard Cemented Cup Without snap fit Assembly | 48/28 |

| CFNG-48/32 | Standard Cemented Cup Without snap fit Assembly | 48/32 |

| CFNG-50/28 | Standard Cemented Cup Without snap fit Assembly | 50/28 |

| CFNG-50/32 | Standard Cemented Cup Without snap fit Assembly | 50/32 |

| CFNG-52/28 | Standard Cemented Cup Without snap fit Assembly | 52/28 |

| CFNG-52/32 | Standard Cemented Cup Without snap fit Assembly | 52/32 |

| CFNG-52/36 | Standard Cemented Cup Without snap fit Assembly | 52/36 |

| CFNG-56/28 | Standard Cemented Cup Without snap fit Assembly | 56/28 |

| CFNG-56/32 | Standard Cemented Cup Without snap fit Assembly | 56/32 |

| CFNG-56/36 | Standard Cemented Cup Without snap fit Assembly | 56/36 |

| CFNG-56/40 | Standard Cemented Cup Without snap fit Assembly | 56/40 |

| CFNG-60/28 | Standard Cemented Cup Without snap fit Assembly | 60/28 |

| CFNG-60/32 | Standard Cemented Cup Without snap fit Assembly | 60/32 |

| CFNG-60/36 | Standard Cemented Cup Without snap fit Assembly | 60/36 |

| CFNG-60/40 | Standard Cemented Cup Without snap fit Assembly | 60/40 |

| CING-38/22 | 10° Cemented Cup Assembly | 38/22 |

| CING-40/22 | 10° Cemented Cup Assembly | 40/22 |

| CING-42/22 | 10° Cemented Cup Assembly | 42/22 |

| CING-44/22 | 10° Cemented Cup Assembly | 44/22 |

| CING-44/28 | 10° Cemented Cup Assembly | 44/28 |

| CING-46/28 | 10° Cemented Cup Assembly | 46/28 |

| CING-48/28 | 10° Cemented Cup Assembly | 48/28 |

| CING-48/32 | 10° Cemented Cup Assembly | 48/32 |

| CING-50/28 | 10° Cemented Cup Assembly | 50/28 |

| CING-50/32 | 10° Cemented Cup Assembly | 50/32 |

| CING-52/28 | 10° Cemented Cup Assembly | 52/28 |

| CING-52/32 | 10° Cemented Cup Assembly | 52/32 |

| CING-52/36 | 10° Cemented Cup Assembly | 52/36 |

| CING-56/28 | 10° Cemented Cup Assembly | 56/28 |

| CING-56/32 | 10° Cemented Cup Assembly | 56/32 |

| CING-56/36 | 10° Cemented Cup Assembly | 56/36 |

| CING-56/40 | 10° Cemented Cup Assembly | 56/40 |

| CING-60/28 | 10° Cemented Cup Assembly | 60/28 |

| CING-60/32 | 10° Cemented Cup Assembly | 60/32 |

| CING-60/36 | 10° Cemented Cup Assembly | 60/36 |

| CING-60/40 | 10° Cemented Cup Assembly | 60/40 |